Applications |

|

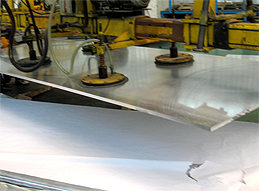

Some of the applications in which cast plate have been used include food machinery aluminium moulding plate and other low pressure molding, electrical heating plates, milling machine bedplate, automatic inspection machine board holder, and screen printer base plate. Wrought aluminium products are also widely applied. The nature of the improvements made to the plate products for use in tool and mold applications involves the following areas: *Improved uniformity in through thickness properties. This is especially important because the products are available in thickness up to 35" in some cases. For applications like low pressure plastic and composite molding including thermoforming and resin transfer molding that require a material with excellent corrosion resistance and weldability, 5*** alloys are preferred. Other applications such as low pressure molding of rubber and other elastomers, which involve temperatures in the 350-400 º F range, necessitate a moderate strength materials with good property retention at moderately elevated temperatures. Here, aluminium foil strip producers offer alloys based on the 2*** series. Another class of applications, particularly injection and compression molding as well as bolsters and force plates, call for high strength properties along with excellent machinability, high polishability, and good shape stability. The 7*** alloy family meets this need well. A survey of wrought tool and mold plate products would wot be complete without mentioning moderate strength alloys of the 6*** series. Specialized versions of 6061 T6 in stress relieved tempers are available both in plate as compressions tress relieved thick 6061 T651. While conventional aluminium tool and mold products have some obvious advantages in this these application areas, the competition if not standing still. Some developing technologies include both aluminum ans steel tools manufactured using rapid prototyping methods, which have been trialed in short production run applications successfully. Rapid manufacturing methods eliminate some of the advantages enjoyed by aluminium in terms of machinability and shorter lead times over conventionally processed steel. This area looks like one that will continue to see significant emphasis and development in the aluminum industry worldwide. |